Thanks to: Frank Barrella, son of S/Sgt Frank L. Barrella, mechanic on the "Irish Lullaby"; Jason Bishop, grandson of Sgt Julian E. Pencovic, crew chief, 39th Squadron; Chris Murphy, daughter of William J. Owens, crew chief on "Gravel Gertie"; Alan Beay, son-in-law of S/Sgt Gordon W. Kirchner, radar mechanic on "Flak Alley Sally".

- The Aircraft Ground Crews - who were assigned to a particular aircraft.

- The Squadron Service Personnel - who provided daily support for the men and the machines.

- The Service Groups - who initially handled only the big jobs and later provided most of the ground crew personnel.

The ground crews were probably the hardest working men on the base. They had the difficult task of making sure that, not only was the B-29 assigned to them ready for the next mission, but would carry the crew all the way to Japan and back. This was a difficult task under the best of conditions, particularly given the mechanical quirks of the B-29. They worked indoors and outdoors, in all kinds of weather, day and night. Their only rest was when the aircraft on a mission. But, even then, they spent most of the time worrying about whether the plane and crew would return safely.

When the 6th Bomb Group arrived at Tinian, theUSAAF was still using the "Crew Chief System". In this system, a Crew Chief [MOS 750] was permanently assigned to each airplane. In addition, the crew chief had an assistant crew chief and five Airplane and Engine Mechanics [MOS 747] to help with the maintenance of the plane. The mechanic was qualified in all systems except armament, camera, and radio. The crew chief was a master mechanic. The crew chief and his crew members maintained the airframe, engines, controls, and accessory systems. Each Squadron had a certain number of specialists, including Armorers and Electrical Technician [MOS 685].

The major advantage with this system is that each ground crew had a special knowledge and attachment to their airplane. A disadvantage was that some ground crews ended up working harder than others, depending on the condition of the aircraft.

During the latter part of the war, the USAAF changed from the "Crew Chief System" to the Post Line Maintenance System". In this system a much smaller ground crew was permanently assigned to each airplane. These included a Crew Chief , an assistant crew chief and only one Airplane and Engine Mechanic. To supplement their efforts, the Crew Chief called upon specialists from the Service Groups.

As a result of this change, most members of the ground crews were reassigned to the Service Groups where they would be called upon as needed. While most of the men probably missed being attached to a particular airplane, this change helped maximize the workforce by assigning individuals to airplanes based on need.

A combat group had a commander for all group maintenance, which was done in a maintenance section headed by an engineering officer. The section was divided into two branches: a flying line maintenance branch and a production line maintenance branch, each headed by an assistant engineering officer. The flying line maintenance branch was broken into four units: one each for maintenance, servicing, armament, and communications. This branch was responsible for servicing, preflight, daily and 25-hour inspections, filling out forms, all contact with aircrews, replacement of aircraft and engine units (unless it would involve excessive out-of-commission time), and accomplishment of technical order changes.

The production line maintenance branch consisted of 14 units: one each for cockpit and cabin, cleaning, flight controls and surfaces, hydraulic and landing gear, engine, fuel and oil, electrical, instrument, propeller, armament, communications, metal repair, ground equipment repair, and parachute. This branch was responsible for washing and cleaning; accomplishment of 50-hour, 100-hour, and other periodic inspections; engine changes: and technical order changes beyond the capability of the flying line maintenance branch. The production branch also changed major assemblies; did metal repair and maintenance and servicing of flight-line and hangar equipment; and prepared engines and aircraft for return to supply or depot and aircraft for return to depot.

"Sergeant Owens was Crew Chief at a base in the Marianas Islands supervising the maintenance of a B-29 aircraft. Working under adverse conditions which frequently involved new problems never before faced in aircraft maintenance, he directed the ground servicing of his place so effectively that it completed 22 combat missions without a mechanical malfunction necessitating early return. Displaying indefatigable zeal, he devoted exceptionally long hours to keep the plane operational, sometimes leading his crew in repairing battle damage suffered in one raid while simultaneously readying the bomber for its next mission."

| The ground crew of "Irish Lullaby". As can be seen, the ground crews spent a lot of time working outdoors in the hot sun. Shirts were optional. |

Photo courtesy of Frank Barrella, all rights reserved

|

|---|

| An artist and his critics at work. The ground crews took great pride in their aircraft. The lower half of this aircraft appears to be painted with a dark color that was supposed to prevent detection by searchlights on low level missions. |

Photo courtesy of Frank Barrella, all rights reserved

|

|---|

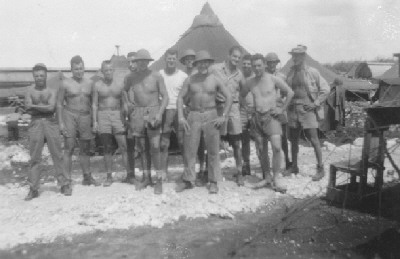

Several of the men who became crew chiefs of the 39th Squadron. This was probably taken in Grand Island Nebraska, prior to departing for Tinian.

Standing - Left to Right: Sgt Joseph A. Plax, M/Sgt Hildry O. Strickland (Crew Chief), S/Sgt R. Martelly, Jr. (Crew Chief),

T/Sgt Henry A. Rowen (Crew Chief, "Grider Gal"), T/Sgt Jack A. Chaney (Crew Chief),

M/Sgt Henry H. Kolthoff (Crew Chief, "Snugglebunny"),

Sgt Julian E. Pencovic (Crew Chief)

Kneeling - Left to Right: S/Sgt S. T. Cieselski, Sgt Otis B. Cox, S/Sgt James E. Kitchel,

S/Sgt Ralph A. Francescone (Crew Chief), M/Sgt Joseph P. G. Cote (Crew Chief).

Possibly the ground crew of M/Sgt Joseph P. G. Cote assigned to "Trigger Mortis II". The third man from the right may be Supply Sgt Anthony Ferraro of the 359th air material squadron.

T/Sgt Henry H. Kolthoff and ground crew in front of "Snugglebunny".

| M/Sgt William J. Owens was crew chief on "Gravel Gertie which "completed 22 combat missions without a mechanical malfunction necessitating an early return". He received a Citation for Meritorious Service (see quote above). |

Photo courtesy of Chris Murphy, all rights reserved

|

|---|

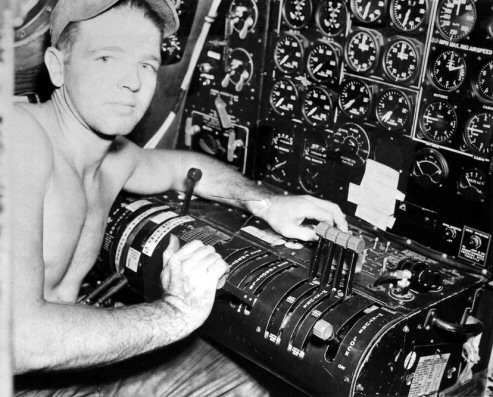

| Gordon Kirchner gets a break from working on "Flak Alley Sally" to take a look outdoors. All that glass caused the B-29 to become quite hot. And there was no electricity to run fans. |

Photo courtesy of Allen Beay, all rights reserved.

|

|---|

Aircraft Mechanic/Auxiliary Mechanic [MOS 747]

Armorers [MOS 911]

CFC Maintenance

Communications

Electrical

Engineering

Medical

Mess [MOS 824]

Operations

Ordnance

Personal Equipment

Photography

Propeller Shop

Radar SectionRadar Mechanic, Bombardment [MOS 867]Radio Shop

Radar Countermeasures [MOS 852]

Refuelers [all Naval personnel on Tinian]

Sheet Metal

|

39th Squadron Armorers Armorers loaded each aircraft with the correct mix of bombs and bullets prior to each mission. They accomplished this task with great care and had to make sure that the bombs were loaded properly so that they would drop properly. A "hung" bomb could ruin a mission. |

Photo courtesy of Jason Bishop, all rights reserved

|

|---|

|

39th Squadron Armorers Another picture of the armorers. S/Sgt John O. "Jack" Nichols, 5th from right. |

Photo courtesy of Nick Nichols, all rights reserved

|

|---|---|

|

On Tinian, the Navy handled the refueling operations. They offloaded the fuel from the tanker ships in the harbor and loaded it into large refueling trucks that were capable of filling up a B-29. It appears that there was some kind of pipeline that ran from the harbor onto the docks. It is not clear whether the ships offloaded to a large temporary storage tank or whether the ships themselves were used as floating fuel tanks. |

|

|---|

|

The Motor Pool was in charge of the Group's allotment of trucks and jeeps. Most of the trucks were the 6X6 trucks that appeared everywhere. (The term 6X6 indicates that the truck had 6 wheels and that they were all driven. A jeep is a 4X4 vehicle.) The Group used the 6X6 trucks to transport the air and ground crews to the planes. Officers used the jeeps for personal transport. If you had a friend in the motor pool, you could borrow a jeep to tour the island. |

A truckload of nurses. Always a welcome sight!

|

|---|

|

In addition to the people who worked on the planes, each Squadron had people who were skilled in various administrative functions. Their efforts enabled the Squadrons to function smoothly. Furthermore, they were in Tinian, working along with everyone else. The administrative staff typed, filed and circulated the orders, the requests for supplies and correspondence necessary to win the war. After the war, the Group simply abandoned most of their office equipment, including hundreds of typewriters. It was simply too expensive to transport the equipment. |

Pfc Virgil E. Carson, Teletype Operator, 24th Squadron

|

|---|

|

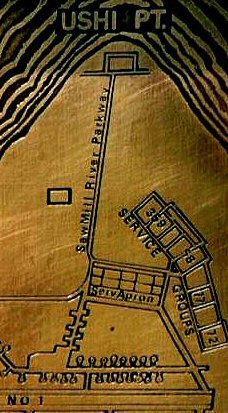

The Service Groups handled jobs that were too big for the regular ground crews, such as 100 hour inspections and engine overhauls. The Service Groups stationed at the northeast corner of North Field include the 359th, 358th, 77th, and 72nd Service Groups. They were kept busy, as some recall that the engines almost never made it to the 100 hour mark. Originally, each aircraft had a full ground crew that handled all of the maintenance for that aircraft. However, during the latter part of the war, almost all of the ground crew, except for the crew chief and a couple of assistants were assigned to the 72nd Air Service Group. The 72nd Air Services Group included the:

Here is a partial list of the men of the 72nd ASG. |

|

|---|

Engine overhaul on a B-29. A special crew handled these tasks, performing them at the revetment. Even with all this equipment, an overhaul took more than a day to complete.

|

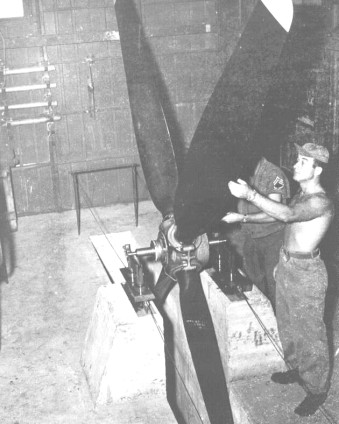

The propeller shop ("prop shop") was part of the 535th Air Engineering Squadron. The prop shop made sure that the props were in good shape. This involved "dressing" the props to remove small nicks, balancing them to eliminate vibration and adjusting the various mechanisms that control pitch and feathering. T/Sgt Ellis Reece Bethany was in charge of the prop shop. |

Photo from Raymond J. Biedenbach Collection

|

|---|

|

Members of the 72nd ASG Prop Shop inspect a Japanese copy of the Hamilton-Standard propeller. All agreed that the workmanship was outstanding. |

Photo courtesy of ____, all rights reserved.

|

|---|